An Introduction to Supply Chain Management

Ram Ganeshan

Terry P. Harrison

Department of Management Science and Information Systems

303 Beam Business Building

Penn State University

University Park, PA 16802 U.S.A.

Email: Ganeshan (rxg112@silmaril.smeal.psu.edu),

Harrison (hbx@psu.edu)

A

supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished products, and the distribution of these finished products to customers. Supply chains exist in both service and manufacturing organizations, although the complexity of the chain may vary greatly from industry to industry and firm to firm.

Below is an example of a very simple supply chain for a single product, where raw material is procured from vendors, transformed into finished goods in a single step, and then transported to distribution centers, and ultimately, customers. Realistic supply chains have multiple end products with shared components, facilities and capacities. The flow of materials is not always along an arborescent network, various modes of transportation may be considered, and the bill of materials for the end items may be both deep and large.

Traditionally, marketing, distribution, planning, manufacturing, and the purchasing organizations along the supply chain operated independently. These organizations have their own objectives and these are often conflicting. Marketing's objective of high customer service and maximum sales dollars conflict with manufacturing and distribution goals. Many manufacturing operations are designed to maximize throughput and lower costs with little consideration for the impact on inventory levels and distribution capabilities. Purchasing contracts are often negotiated with very little information beyond historical buying patterns. The result of these factors is that there is not a single, integrated plan for the organization---there were as many plans as businesses. Clearly, there is a need for a mechanism through which these different functions can be integrated together. Supply chain management is a strategy through which such an integration can be achieved.

Supply chain management is typically viewed to lie between fully vertically integrated firms, where the entire material flow is owned by a single firm, and those where each channel member operates independently. Therefore coordination between the various players in the chain is key in its effective management. Cooper and Ellram [1993] compare supply chain management to a well-balanced and well-practiced relay team. Such a team is more competitive when each player knows how to be positioned for the hand-off. The relationships are the strongest between players who directly pass the baton, but the entire team needs to make a coordinated effort to win the race.

Supply Chain Decisions

We classify the decisions for supply chain management into two broad categories -- strategic and operational. As the term i

mplies, strategic decisions are made typically over a longer time horizon. These are closely linked to the corporate strategy (they sometimes {\it are} the corporate strategy), and guide supply chain policies from a design perspective. On the other hand, operational decisions are short term, and focus on activities over a day-to-day basis. The effort in these type of decisions is to effectively and efficiently manage the product flow in the "strategically" planned supply chain.

There are four major decision areas in supply chain management: 1) location, 2) production, 3) inventory, and 4) transportation (distribution), and there are both strategic and operational elements in each of these decision areas.

Location Decisions

The geographic placement of production facilities, stocking points, and sourcing points is the natural first step in creating a supply chain. The location of facilities involves a commitment of resources to a long-term plan. Once the size, number, and location of these are determined, so are the possible paths by which the product flows through to the final customer. These decisions are of great significance to a firm since they represent the basic strategy for accessing customer markets, and will have a considerable impact on revenue, cost, and level of service. These decisions should be determined by an optimization routine that considers production costs, taxes, duties and duty drawback, tariffs, local content, distribution costs, production limitations, etc. (See Arntzen, Brown, Harrison and Trafton [1995] for a thorough discussion of these aspects.) Although location decisions are primarily strategic, they also have implications on an operational level.

Production Decisions

The strategic decisions include what products to produce, and which plants to produce them in, allocation of suppliers to plants, plants to DC's, and DC's to customer markets. As before, these decisions have a big impact on the revenues, costs and customer service levels of the firm. These decisions assume the existence of the facilities, but determine the exact path(s) through which a product flows to and from these facilities. Another critical issue is the capacity of the manufacturing facilities--and this largely depends the degree of vertical integration within the firm. Operational decisions focus on detailed production scheduling. These decisions include the construction of the master production schedules, scheduling production on machines, and equipment maintenance. Other considerations include workload balancing, and quality control measures at a production facility.

Inventory Decisions

These refer to means by which inventories are managed. Inventories exist at every stage of the supply chain as either raw materials, semi-finished or finished goods. They can also be in-process between locations. Their primary purpose to buffer against any uncertainty that might exist in the supply chain. Since holding of inventories can cost anywhere between 20 to 40 percent of their value, their efficient management is critical in supply chain operations. It is strategic in the sense that top management sets goals. However, most researchers have approached the management of inventory from an operational perspective. These include deployment strategies (push versus pull), control policies --- the determination of the optimal levels of order quantities and reorder points, and setting safety stock levels, at each stocking location. These levels are critical, since they are primary determinants of customer service levels.

Transportation Decisions

The mode choice aspect of these decisions are the more strategic ones. These are closely linked to the inventory decisions, since the best choice of mode is often found by trading-off the cost of using the particular mode of transport with the indirect cost of inventory associated with that mode. While air shipments may be fast, reliable, and warrant lesser safety stocks, they are expensive. Meanwhile shipping by sea or rail may be much cheaper, but they necessitate holding relatively large amounts of inventory to buffer against the inherent uncertainty associated with them. Therefore customer service levels, and geographic location play vital roles in such decisions. Since transportation is more than 30 percent of the logistics costs, operating efficiently makes good economic sense. Shipment sizes (consolidated bulk shipments versus Lot-for-Lot), routing and scheduling of equipment are key in effective management of the firm's transport strategy.

Supply Chain Modeling Approaches

Clearly, each of the above two levels of decisions require a different perspective. The strategic decisions are, for the most part, global or "all encompassing" in that they try to integrate various aspects of the supply chain. Consequently, the models that describe these decisions are huge, and require a considerable amount of data. Often due to the enormity of data requirements, and the broad scope of decisions, these models provide approximate solutions to the decisions they describe. The operational decisions, meanwhile, address the day to day operation of the supply chain. Therefore the models that describe them are often very specific in nature. Due to their narrow perspective, these models often consider great detail and provide very good, if not optimal, solutions to the operational decisions.

To facilitate a concise review of the literature, and at the same time attempting to accommodate the above polarity in modeling, we divide the modeling approaches into three areas --- Network Design, ``Rough Cut" methods, and simulation based methods. The network design methods, for the most part, provide normative models for the more strategic decisions. These models typically cover the four major decision areas described earlier, and focus more on the design aspect of the supply chain; the establishment of the network and the associated flows on them. "Rough cut" methods, on the other hand, give guiding policies for the operational decisions. These models typically assume a "single site" (i.e., ignore the network) and add supply chain characteristics to it, such as explicitly considering the site's relation to the others in the network. Simulation methods is a method by which a comprehensive supply chain model can be analyzed, considering both strategic and operational elements. However, as with all simulation models, one can only evaluate the effectiveness of a pre-specified policy rather than develop new ones. It is the traditional question of "What If?" versus "What's Best?".

Network Design Methods

As the very name suggests, these methods determine the location of production, stocking, and sourcing facilities, and paths the product(s) take through them. Such methods tend to be large scale, and used generally at the inception of the supply chain. The earliest work in this area, although the term "supply chain" was not in vogue, was by Geoffrion and Graves [1974]. They introduce a multicommodity logistics network design model for optimizing annualized finished product flows from plants to the DC's to the final customers. Geoffrion and Powers [1993] later give a review of the evolution of distribution strategies over the past twenty years, describing how the descendants of the above model can accommodate more echelons and cross commodity detail.

Breitman and Lucas [1987] attempt to provide a framework for a comprehensive model of a production-distribution system, "PLANETS", that is used to decide what products to produce, where and how to produce it, which markets to pursue and what resources to use. Parts of this ambitious project were successfully implemented at General Motors.

Cohen and Lee [1985] develop a conceptual framework for manufacturing strategy analysis, where they describe a series of stochastic sub- models, that considers annualized product flows from raw material vendors via intermediate plants and distribution echelons to the final customers. They use heuristic methods to link and optimize these sub- models. They later give an integrated and readable exposition of their models and methods in Cohen and Lee [1988].

Cohen and Lee [1989] present a normative model for resource deployment in a global manufacturing and distribution network. Global after-tax profit (profit-local taxes) is maximized through the design of facility network and control of material flows within the network. The cost structure consists of variable and fixed costs for material procurement, production, distribution and transportation. They validate the model by applying it to analyze the global manufacturing strategies of a personal computer manufacturer.

Finally, Arntzen, Brown, Harrison, and Trafton [1995] provide the most comprehensive deterministic model for supply chain management. The objective function minimizes a combination of cost and time elements. Examples of cost elements include purchasing, manufacturing, pipeline inventory, transportation costs between various sites, duties, and taxes. Time elements include manufacturing lead times and transit times. Unique to this model was the explicit consideration of duty and their recovery as the product flowed through different countries. Implementation of this model at the Digital Equipment Corporation has produced spectacular results --- savings in the order of $100 million dollars.

Clearly, these network-design based methods add value to the firm in that they lay down the manufacturing and distribution strategies far into the future. It is imperative that firms at one time or another make such integrated decisions, encompassing production, location, inventory, and transportation, and such models are therefore indispensable. Although the above review shows considerable potential for these models as strategic determinants in the future, they are not without their shortcomings. Their very nature forces these problems to be of a very large scale. They are often difficult to solve to optimality. Furthermore, most of the models in this category are largely deterministic and static in nature. Additionally, those that consider stochastic elements are very restrictive in nature. In sum, there does not seem to yet be a comprehensive model that is representative of the true nature of material flows in the supply chain.

Rough Cut Methods

These models form the bulk of the supply chain literature, and typically deal with the more operational or tactical decisions. Most of the integrative research (from a supply chain context) in the literature seem to take on an inventory management perspective. In fact, the term "Supply Chain" first appears in the literature as an inventory management approach. The thrust of the rough cut models is the development of inventory control policies, considering several levels or echelons together. These models have come to be known as "multi-level" or "multi-echelon" inventory control models. For a review the reader is directed to Vollman et al. [1992].

Multi-echelon inventory theory has been very successfully used in industry. Cohen et al. [1990] describe "OPTIMIZER", one of the most complex models to date --- to manage IBM's spare parts inventory. They develop efficient algorithms and sophisticated data structures to achieve large scale systems integration.

Although current research in multi-echelon based supply chain inventory problems shows considerable promise in reducing inventories with increased customer service, the studies have several notable limitations. First, these studies largely ignore the production side of the supply chain. Their starting point in most cases is a finished goods stockpile, and policies are given to manage these effectively. Since production is a natural part of the supply chain, there seems to be a need with models that include the production component in them. Second, even on the distribution side, almost all published research assumes an arborescence structure, i. e. each site receives re-supply from only one higher level site but can distribute to several lower levels. Third, researchers have largely focused on the inventory system only. In logistics-system theory, transportation and inventory are primary components of the order fulfillment process in terms of cost and service levels. Therefore, companies must consider important interrelationships among transportation, inventory and customer service in determining their policies. Fourth, most of the models under the "inventory theoretic" paradigm are very restrictive in nature, i.e., mostly they restrict themselves to certain well known forms of demand or lead time or both, often quite contrary to what is observed.

The preceding sections are a selective overview of the key concepts in the supply chain literature. Following is a list of recommended reading for a quick introduction to the area.

Bibliography

- Arntzen, B. C., G. G. Brown, T. P. Harrison, and L. Trafton. Global Supply Chain Management at Digital Equipment Corporation. Interfaces, Jan.-Feb., 1995.

- Ballou, R. H. 1992. Business Logistics Management, Prentice Hall, Englewood Cliffs, NJ, Third Edition.

- Breitman, R. L., and J. M. Lucas. 1987. PLANETS: A Modeling System for Business Planning. Interfaces, 17, Jan.-Feb., 94-106.

- Cohen, M. A. and H. L. Lee. 1985. Manufacturing Strategy Concepts and Methods, in Kleindorfer, P. R. Ed., The Management of Productivity and Technology in Manufacturing, 153- 188.

- Cohen, M. A. and H. L. Lee. 1988. Strategic Analysis of Integrated Production-Distribution Systems: Models and Methods. Operations Research, 36, 2, 216-228.

- Cohen, M. A. and H. L. Lee. 1989. Resource Deployment Analysis of Global Manufacturing and Distribution Networks. Journal of Manufacturing and Operations Management, 81-104.

- Cooper, M. C., and L. M. Ellram. 1993. Characteristics of Supply Chain Management and the Implications for Purchasing and Logistics Strategy. The International Journal of Logistics Management, 4, 2, 13-24.

- Deuermeyer, B. and L. B. Schwarz. 1981. A Model for the Analysis of System Service Level in Warehouse/ Retailer Distribution Systems: The Identical Retailer Case, in: L. B. Schwarz (ed.), Studies in Management Sciences, Vol. 16--Multi-Level Production / Inventory Control Systems, North-Holland, Amsterdam, 163-193.

- Geoffrion, A., and G. Graves. 1974. Multicommodity Distribution System Design by Benders Decomposition. Management Science, 29, 5, 822-844.

- Geoffrion, A., and R. Powers. 1993. 20 Years of strategic Distribution System Design: An Evolutionary Perspective, Interfaces. (forthcoming)

- Houlihan, J. B. 1985. International Supply Chain Management. International Journal of Physical Distribution and Materials Management, 15, 1, 22-38.

- Lee, H. L., and C. Billington. 1992. Supply Chain Management: Pitfalls and Opportunities. Sloan Management Review, 33, Spring, 65-73.

- Lee, H. L., and C. Billington. 1993. Material Management in Decentralized Supply Chains. Operations Research, 41, 5, 835-847.

- Masters, J. M. 1993. Determination of Near-Optimal Stock Levels for Multi-Echelon Distribution Inventories. Journal of Business Logistics, 14, 2, 165-195.

- Schwarz, L. B. 1981. Introduction in: L. B. Schwarz (ed.), Studies in Management Sciences, Vol. 16--Multi-Level Production / Inventory Control Systems, North-Holland, Amsterdam, 163-193.

- Stenross, F. M., and G. J. Sweet. 1991. Implementing an Integrated Supply Chain in Annual Conference Proceedings, Oak Brook, Ill: Council of Logistics Management, Vol. 2, 341-351.

- Vollman, T. E., W. L. Berry, and D. C. Whybark. 1992. Manufacturing Planning and Control Systems, Irwin, Homewood, IL.

Refers to: Production planning, inventory management, distribution and transportation, mathematical programming

Referenced by:

Contributors: Ram Ganeshan (rxg112@silmaril.smeal.psu.edu), Terry Harrison (hbx@psu.edu)

Status: Work that is updated on a regular basis

Last Update: 22 May 1995

Terry P. Harrison, hbx@psu.edu

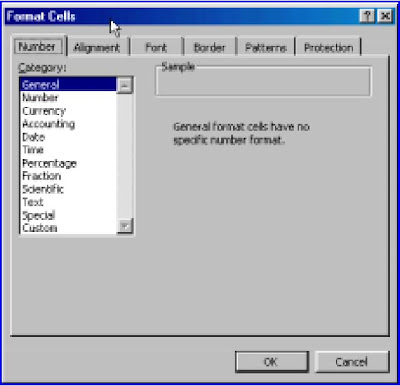

Excel General

Excel General